Dust Collection

In Your Workplace—Clean Air Matters!

Whether it be a wood shop, machine shop or a manufacturing plant—your employees need to feel safe so they can perform their very best.

We offer a wide range of versatile and effective clean air solutions tailored perfectly to your needs and square footage—making your working environment well ventilated and safe.

Clean, fresh air is vitally important.

A quick list of possible contaminants include:

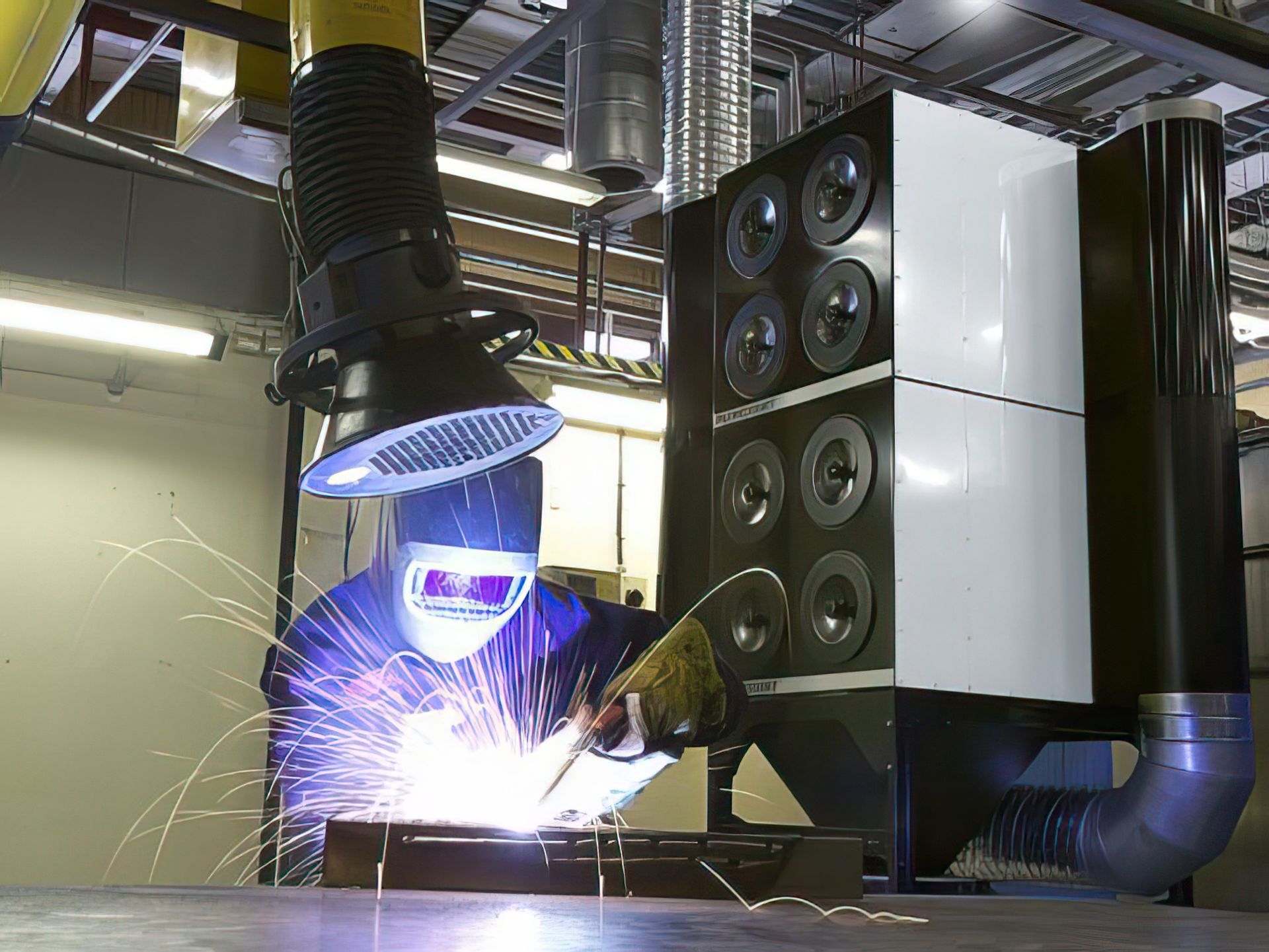

Welding fumes

Grinding dust and particles

Oil mists

Gas-emitting paints and chemicals

Fine powders

Saw dust & machining dust

Paper mill vapers

Fumes/Vapers

Looking for the right product? We’re here to help.

Call us at 416.410.0035, email us at info@thetinknockers.com or use our form and we’ll contact you.

We have the right products to keep your air clean

We sell, install and fully service a multitude of high performing products to keep your shop efficient and your air quality at its best. We have the expertise to advise the right products to suit you perfectly and ensure your workplace has the clean, fresh air your employees deserve.

A few of our key products

Below is a simplified list of some of the effective products we offer.

MistEliminator

Oil mist and oil smoke can quickly arise when using metalworking fluids to lubricate and cool equipment during the operation process. These fine molecules need to be captured quickly to ensure workplace safety. The Mist Eliminator’s unique modular design can be tailored for your specific needs. Whether you produce small or large amounts of oil mist or oil smoke, the need to recirculate or channel that hazardous air outside and replace it with fresh, clean air is vital. This product is a great solution for nearly any environment, effectively capturing these contaminants and keeping your air clean.

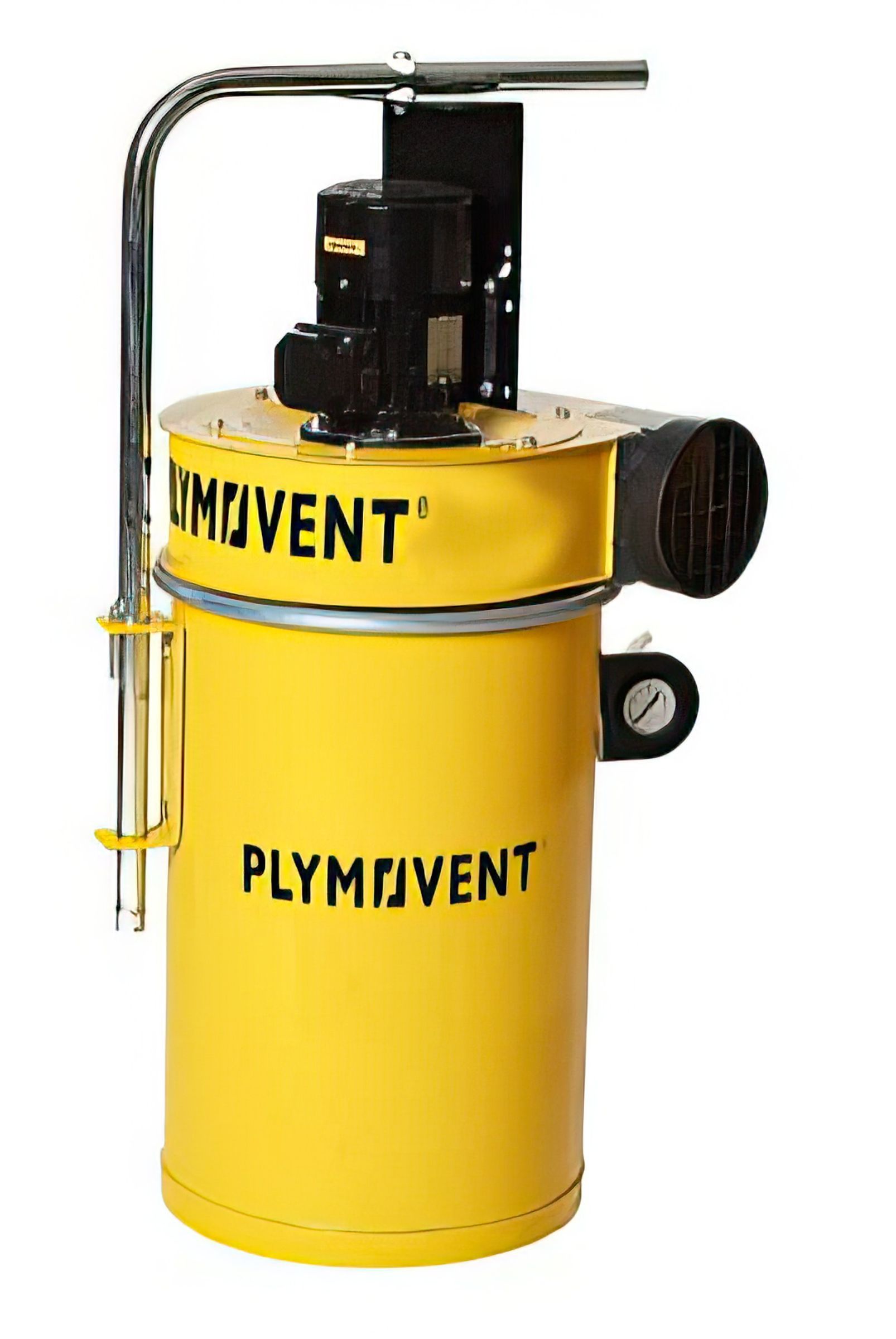

MultiDust®Bank

This low cost of ownership solution is one that grows with you as your needs increase. It provides efficient and effective filtration of dust and fumes. The modular design (ranging from 2 up to 64 cartridges) makes it the perfect fit for businesses set to grow and expand their operation. It is also available in two, plug-and-play versions making it simple and easy to install so you can have effective filtration quickly.

Diluter System

The Diluter system is a stand-alone general filtration system focused on reducing and controlling the concentration of welding fumes in your workplace. It does its job to ensure legal limits for welding fumes are not exceeded. It’s ideal for large work areas where extraction hoods and source extraction units are not feasible due to large work pieces being constructed or limited opportunity to install ductwork.

Push-Pull Systems

Suitable for large areas where source capture is simply not possible. This system extracts harmful gases and airborne particles and intelligently filters the air using an automated, pneumatic cleaning system. The fan system continues to pull bad air in to be cleaned and then pushes the safe, filtered air back into the workplace for re-circulation. Advantages include low noise levels, low cost of ownership, reduction of fine dust and safely removing clouds of fumes.

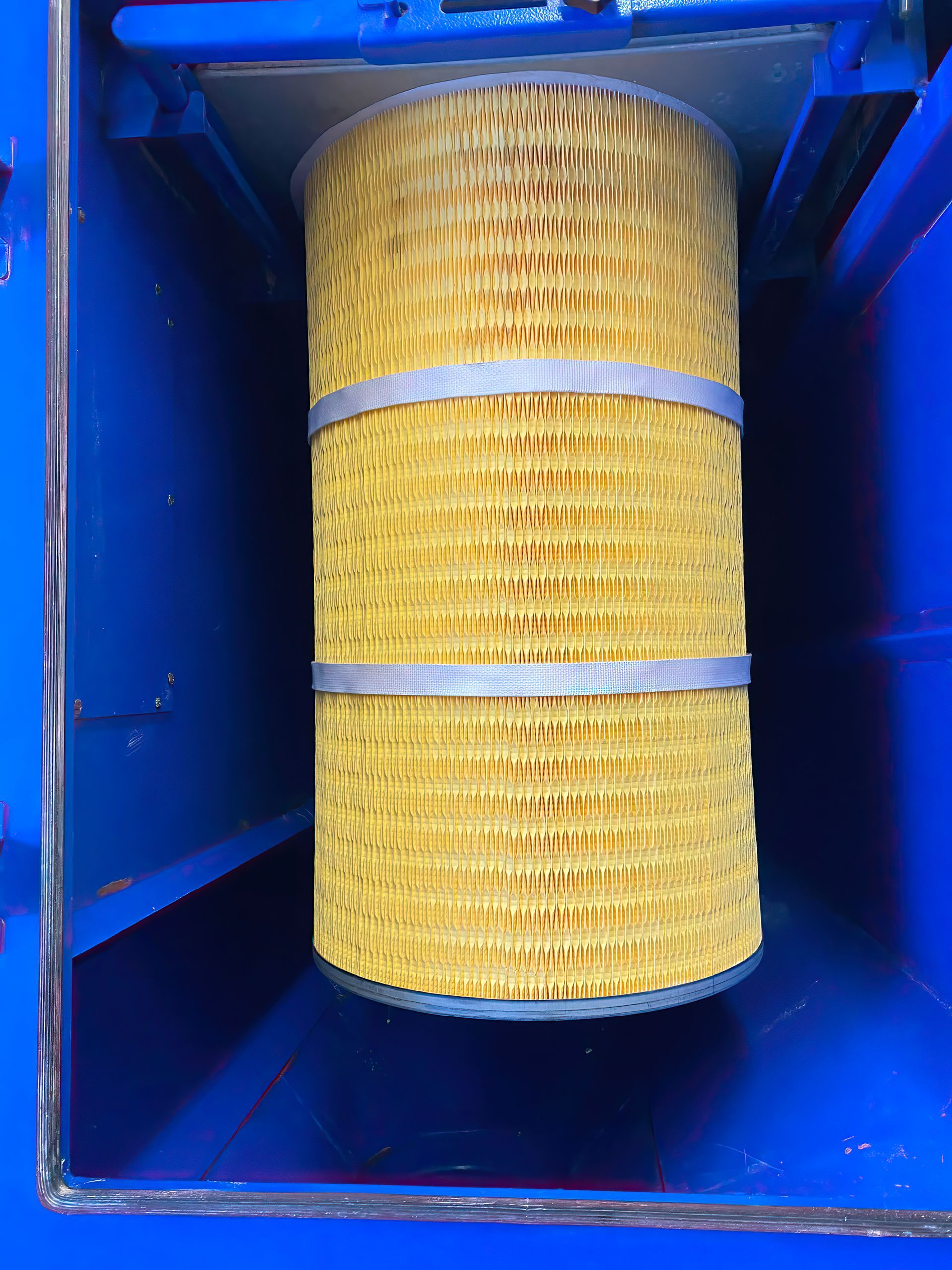

What About Filters?

A huge component to the efficiency of your unit is the filter. If your filter is dirty and clogged – efficiency can go way down and even though you hear your system running, it may become ineffective in this condition. We offer a regular maintenance schedule to ensure your unit is running at peak performance and your employees are breathing clean air. We tailor your maintenance program to you based on how many hours a week your work team is working in their environment.

Having a preventative maintenance program in place is very important. Here are a few key advantages:

We ensure your filtration equipment is running to fully capacity and efficiency

We inspect and replace belts when required. A broken belt has the capacity to stop production and shut your shop down

We replace filters such as fabric filter bag, baghouse filter bags, cartridge filter bags and envelope filter bags

We oil and lube components to avoid wear and keep everything running smoothly

We diagnose your entire system to determine if any component is wearing heavily or about to break

Contact us to learn more about our service contracts.

Servicing Ontario with Industrial Clean Air Solutions

t: 416.410.0035 (Toronto)

t: 905.432.9702 (Durham)

toll free: 1.855.413.3095

info@thetinknockers.com

500 Wentworth Street E, Unit 15

Oshawa, ON L1H-3V9

Request for Quote

I would like more information about clean air solutions for my business.

Contact Us

Thank you for contacting us.

We will get back to you as soon as possible.

All Rights Reserved | The Tin Knockers